2 products

-

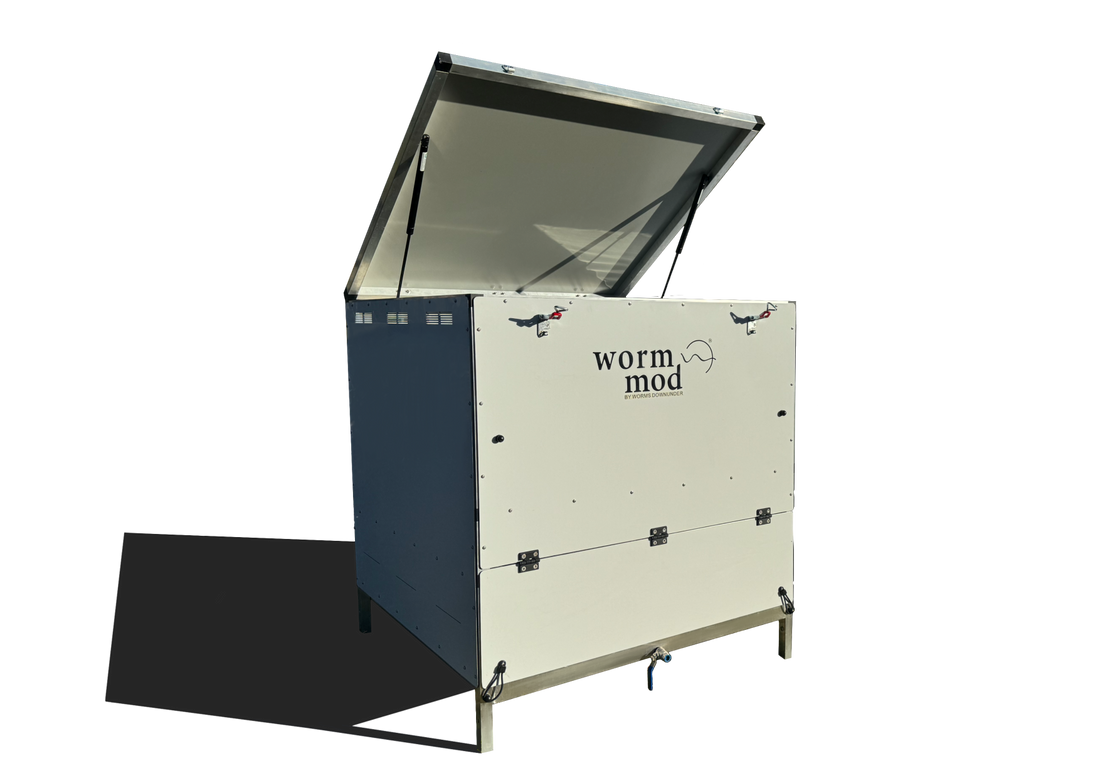

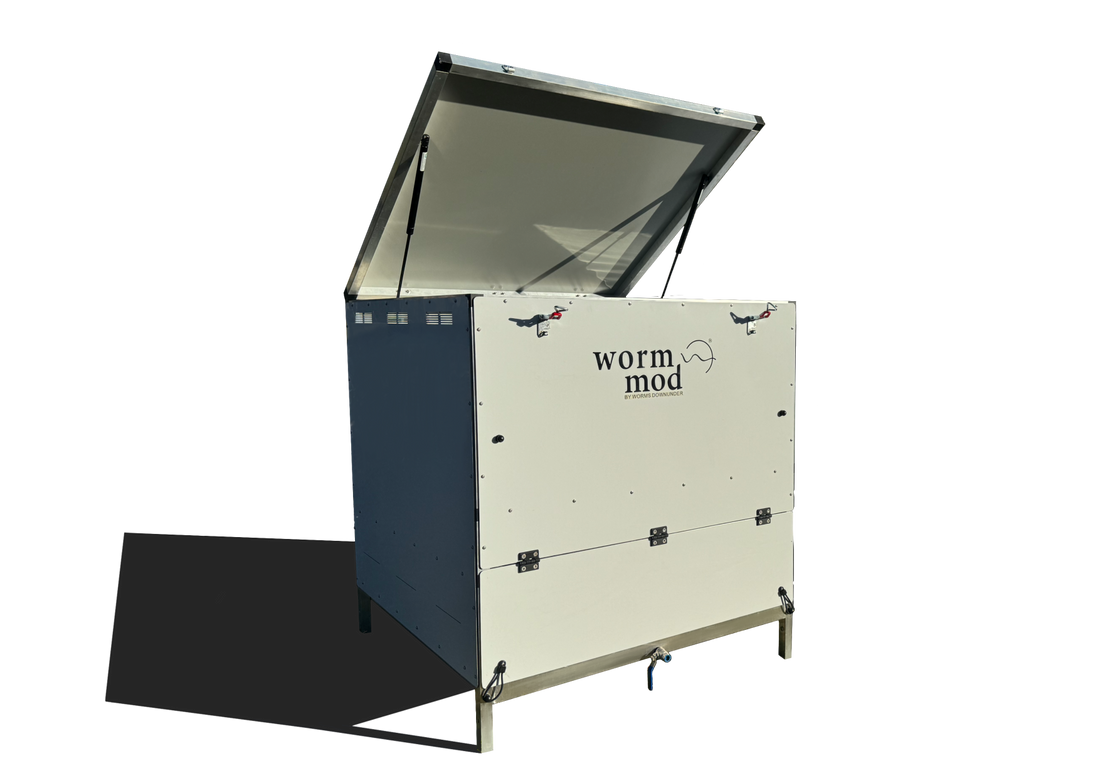

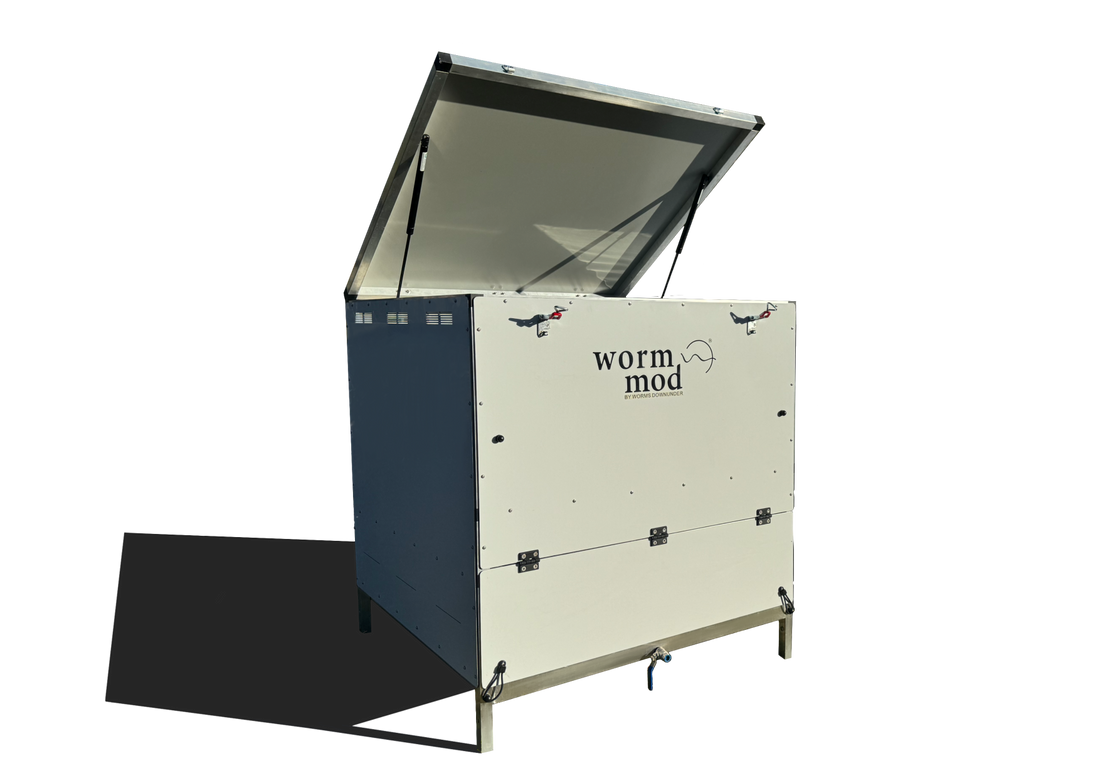

Assembled Worm Mod Units - Large-scale Worm FarmVendor:Assembled Worm Mod Units - Large-scale Worm FarmWorms Downunder

Assembled Worm Mod Units - Large-scale Worm FarmVendor:Assembled Worm Mod Units - Large-scale Worm FarmWorms Downunder- Regular price

-

$3,425.00 - Regular price

-

- Sale price

-

$3,425.00

Quick view

-

Flat-Packed Worm Mod - Large-scale Worm Farm UnitsVendor:Flat-Packed Worm Mod - Large-scale Worm Farm UnitsWorms Downunder

Flat-Packed Worm Mod - Large-scale Worm Farm UnitsVendor:Flat-Packed Worm Mod - Large-scale Worm Farm UnitsWorms Downunder- Regular price

-

$3,000.00 - Regular price

-

- Sale price

-

$3,000.00

Quick view

What is a Worm Farm?

Worm farming, also known as vermicomposting, is the process of using compost worms to convert organic matter into microbe and nutrient rich vermicompost (worm castings). Worms can process anything that was once living into worm cast, a stable humus-like substance, abundant in a diverse range of beneficial microbes.

WDU’s Worm Farm units are predominantly used by farmers looking to convert their on-farm inputs (hay, animal manures, pre-composted matter) into a highly beneficial product for use on their crops or pastures.

The units are also used by organisations for organic waste management. Many cafes, schools and corporations aim to divert their organic waste from landfill and use worms and our worm farms to achieve this. By diverting organic waste from landfill, it reduces the anaerobic breakdown of green waste and therefore, a reduction in methane production.

Benefits of Using Worm Farms to Process Organic Inputs

Worm farming enables the efficient processing of on-site organic matter, including manures, hay, spoiled silage, compost, and FOGO (Food Organics, Garden Organics). Vermicomposting (or worm farming) converts organic waste into highly beneficial, microbially rich vermicompost.

At Worms Downunder, our modular and scalable worm farm systems are designed with high thermal mass for forgiving bedding conditions, high processing capacities and an efficient harvesting system to simplify vermicast collection.

The Benefits of Using Worms to Produce Worm Cast

-

Biological Processing

Worms digest organic matter, mechanically mixing it with mineral particles. This process influences microbial populations, increasing beneficial microbes or suppressing pathogens as needed.

-

Available Feedstocks

Worms will eat anything that was once living. Farmers typically have excellent feedstocks readily available to process into premium worm cast. FOGO inputs are also excellent feedstock options with many organisations claiming an oversupply needing management.

-

Low-maintenance

Requires minimal intervention, with periodic feeding and misting sufficient to maintain production. Unlike traditional composting, no turning is required.

-

Production of Worm Cast and Worm Juice

A single Worm Mod can produce up to 1 Tonne of worm cast per year which can be brewed into 10,000L of worm cast concentrate using basic brewing equipment.

-

Faster Processing

Vermicomposting takes approximately half the time of conventional composting.

-

Odour Control

Well-managed worm farms remain odour-free, producing a natural, earthy scent.

-

Microbial Functions in Vermicast

The unique microbes in worm cast support essential soil functions, including:

- Denitrification & Nitrification – Regulating nitrogen availability.

- Nitrogen Fixation – Converting atmospheric nitrogen into plant-usable forms.

- Methane Oxidation – Reducing greenhouse gas emissions.

- Growth Hormone Production – Stimulating plant development.

- Phosphorus Solubilization – Unlocking bound phosphorus for plant uptake.

- Pathogen Suppression – Enhancing disease resistance in soils.

-

Soil Programs

Producing worm cast on-site reduces costs associated with purchasing liquid biologicals. With some basic equipment, worm cast can be brewed into a liquid form at a fraction of the cost of commercial alternatives.

Frequently Asked Questions

How much waste does a Worm Mod process?

At maximum processing capacity (i.e. most amount of worms & managed well), a single unit will process up to 20L of organic waste per day.

How does a Worm Mod work?

A Worm Mod unit works on a continuous-flow through design. It works on a ‘never full’ principle - Continuously feed in the top and harvest out the bottom using our patent-protected scraper blade system.

What sizes are available?

The Worm Mod is designed with modularity and scalability in mind, allowing customers to expand their system as needed. Additional units can be added to accommodate increased inputs, making it a flexible solution for both small and large operations. The modular design also enables single standalone units or multiple units joined together to form larger worm farm banks.

How long does it take to assemble and set up?

Our flat-packed units can typically be assembled in 1 to 2 hours with basic tools.

Do I need to manage the worms daily?

Worm Mods are low-maintenance. Feeding schedules depend on waste volumes, climates (e.g. misting requirements) and occasional monitoring ensures optimal conditions. Misters can be placed on a timer to set and forget. Manure, hay and compost feedstocks are very easy to manage, foodscrap based feedstocks require a little more attention to ensure carbon:nitrogen ratios are maintained.

Can a Worm Mod be used in hot or cold climates?

Yes, but extreme temperatures require some management. Shade and moisture control help in hot climates, while insulation or strategic positioning helps in colder areas. Worm Mods have a large thermal mass which significantly helps with temperature regulation.

Does it smell or attract pests?

When managed correctly, a Worm Mod is odourless / smells earthy and does not attract pests. Balanced feeding and aeration prevent unwanted smells.

What material are your habitats made from?

Our worm farms are manufactured from sustainable, long lasting and lightweight aluminium frame and panels.

Can my worms be sent with my habitat?

To ensure they arrive safely and happily, we transport your worm farm separately from its tenants. We also like to ensure you’ve set up your habitat (per your helpful manual) so it’s all ready for the arrival of your worms.